How Pipe Relining Works? A Quick Guide to Plumbing Solutions

Pipe relining is fast becoming the #1 way of fixing cracked and broken pipes. Instead of digging up a huge trench in your yard and ruining the lawn. Not only can you fix your damaged pipes but make them stronger, all without making a huge mess. But how does pipe relining work and how is it better than the traditional methods of fixing pipes?

Pipe Relining Before And After

How Does Our Pipe Relining Service Works?

This system is also known as trenchless pipe repair technology because pipe relining doesn’t require digging up a trench. Instead, the pipe is repaired internally with a high-strength epoxy resin. This method can save you thousands of dollars and hours of backbreaking work because the pipe itself doesn’t need to be replaced and excavation equipment doesn’t need to be brought in.

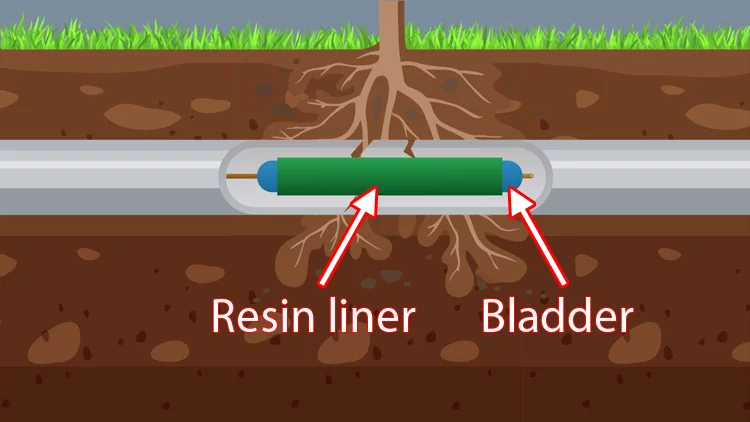

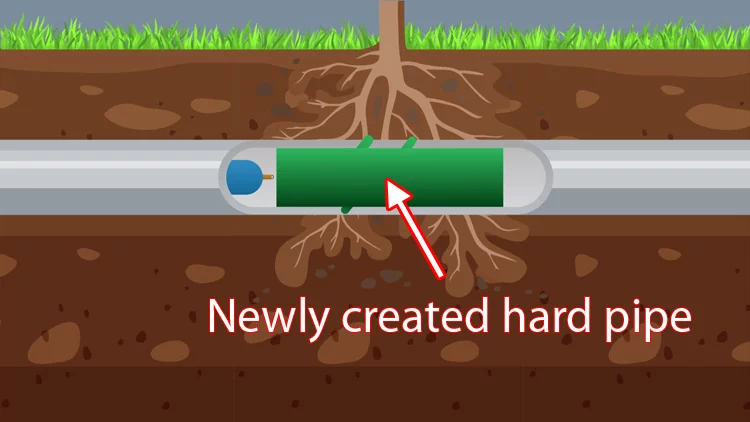

An epoxy resin is placed over an inflatable bladder that is fed down the pipe and put in place. The bladder is then inflated to press the resin against the damaged pipe and left there to harden. This creates a new pipe within the old one that is both stronger and more reliable.

If you believe that there might be an issue with your pipes, give the team at Emergency Drains a call on 1300 524 474. We offer a $0 call-out fee and can be at your door within 90 mins. Our plumbers are experienced with both residential and commercial problems, and if your plumbing problem isn’t solved, it’s free.

Emergency Drains’ 6 Steps to Relining Your Pipes

We use a 6 step process to find, diagnose and repair your damaged pipe.

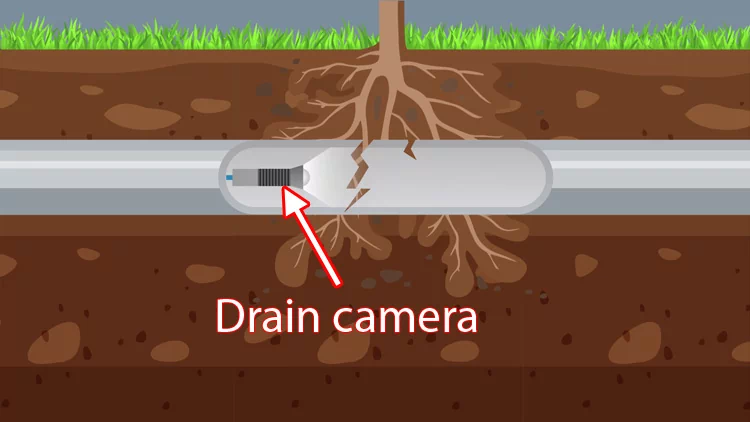

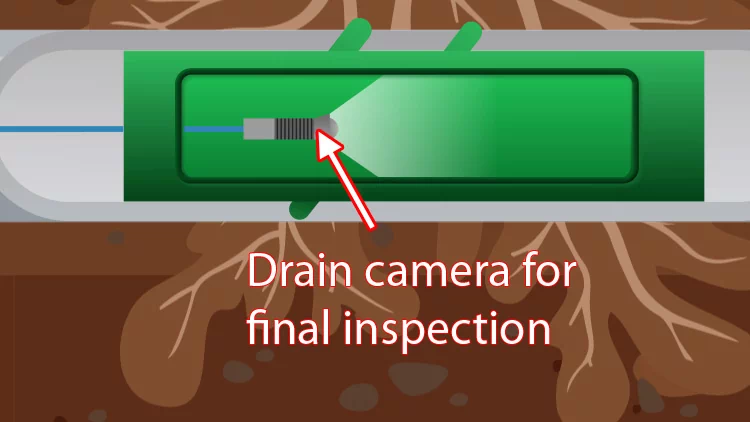

Step 1: Diagnosing the Problem : We feed a CCTV drain camera down your pipe to find out what the issue is and where it’s located.

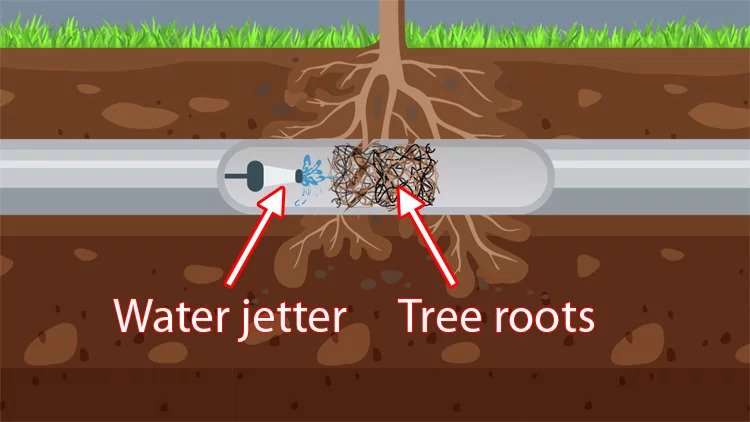

Step 2: Clearing & Cleaning the Pipe: We send through the hydro jet pressure cleaner to clear any blockages and clean the pipe. A high-pressure 5000 PSI cleaner is strong enough to remove tree roots, calcium built-up, and other common blockages.

Step 3: A Resin Liner Is Created: A custom epoxy resin liner is applied around an inflatable bladder. The bladder is inserted down the pipe and positioned to cover the damaged area.

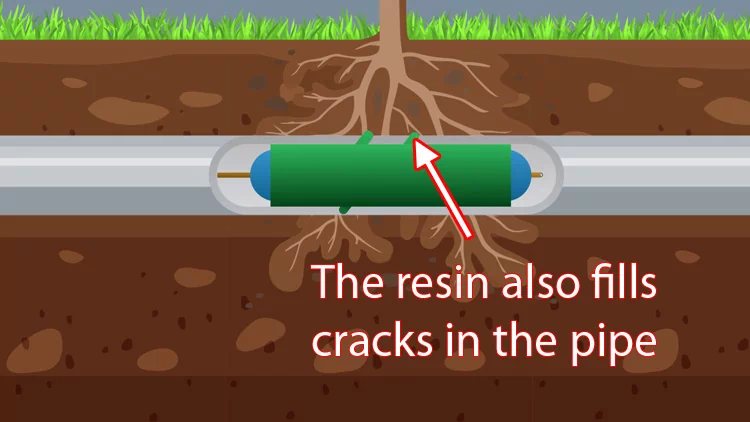

Step 4: Inflating the Bladder: The bladder is inflated until the epoxy resin is pressed against the pipe. The liner is left to cure against the damaged pipe. After an hour the resin becomes solid, creating a solid pipe within the pipe while also filling in the cracks.

Step 5: Removing the Bladder: Once the resin has cured, the bladder is deflated and removed, leaving behind the newly formed pipe.

Step 6: Final Inspection : For the final inspection, we send down the CCTV camera to check the new pipe is properly formed and test the new pipe to make sure water is flowing optimally.

We are so confident in our product that we offer a 30-year warranty on all our pipe relining services, so you can be confident that this new pipe will be long lasting. For more information on our pipe relining services, For more details about our pipe relining services in Sydney, including Stanmore, Lilyfield, Newtown, Camperdown, Glebe, Erskineville, Darlinghurst, Alexandria, Beaconsfield, and Potts Point, visit the Pipe Relining Sydney page on our website.

6 Advantages of Pipe Relining

Pipe relining has many advantages over the traditional method of repairing pipes:

- Save Your Lawn, Garden & Home from Being Dug Up: One of the primary benefits of pipe relining is removing the need to dig up the pipes to fix them. And if the pipes are located under your patio, pathway or any part of your home, getting to those pipes could need extensive excavation work. But with our trenchless pipe relining option, you can avoid any damage to your property.

- It’s a Cost-Effective Pipe Repair Solution: Because sewer pipe relining removes the need to dig a large hole and replace the pipe, you can end up saving thousands. This option eliminates the need for excavation equipment. Fixing your sewer pipe with the traditional method makes a huge mess, and the clean-up costs alone can be a significant addition to the bill.

- Protection From Tree Roots & Other Underground Intrusions: Often, tree roots are the reason you have a cracked and leaking pipe. Plants can detect water underground and will break open the pipe to get to the water. Our pipe relining service will completely seal up the pipe and prevent tree roots from getting through.

- Stronger, Durable & More Reliable: The material used in pipe relining is strong, durable, and long lasting. Relined pipes have a longer life expectancy compared to the pipes on their own. Once you have your pipe relined you can be confident that the pipe will last a long time.

- Improving Pipe Flow Capacity: Concrete and clay pipes have a rough surface and are prone to calcification that can build up inside. These obstructions can slow down the flow of water. The smooth surface of the epoxy pipe lining prevents any build up and promotes the best possible flow capacity

- Time Saving Solution to Fixing Your Pipes: Relining your pipes is way faster than the traditional method of digging up a trench and replacing the pipe. Instead of potentially taking days to complete, it can be done in as little as an hour or 2.

Pipe relining has made what use to be an expensive and time-consuming process, into an easy-to-apply solution. Not only fixing damaged pipes but making them stronger. If you’re looking to have your drains repaired or are experiencing any plumbing issues, give us a call at 1300 524 474 and improve your plumbing today!